Cast Iron Single Stage Centrifugal Pumps

<300m³/hr

<100 Metres

Suitability

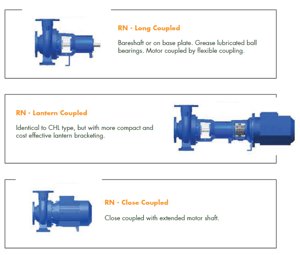

The RN cast iron centrifugal pump have been specifically designed to support high flow rates, pressures and temperatures. The cast iron range is most suited to work optimally within the water supply, heating, air conditioning, cooling and circulation plant formats as well as fire fighting and irrigation.

Applications

As standard, the RN range are suitable for water applications <90°C, but special seals and gaskets are available for suitability <140°C in continuous duty and a maximum working pressure of 10 bar.

EXCLUSIVE UK DISTRIBUTOR

We’re thrilled to announce a new chapter in our partnership with Salvatore Robuschi Pumps! After more than 12 successful years of supplying their pumps under the Crest Pumps name, we are now proud to become the exclusive UK distributor for Salvatore Robuschi’s renowned range of industrial pumps.

This marks an exciting transition as we now promote these high-quality products exclusively under the SR Pumps brand. This new agreement marks a shift to promoting the products exclusively as SR pumps, aligning with our commitment to transparency, quality, and customer trust.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

How much are your pumps REALLY costing you?

Try our BPMA approved Life Cycle Cost calculator to help work out how much you could save... Upfront prices are just the beginning — energy and maintenance make up most of a pump’s lifetime cost. Our LCC calculator breaks it down, helping you compare different pump types and manufacturers to find the best solution for your needs.

-1.jpg?width=300&name=RN%20(2)-1.jpg)

.jpg?width=300&name=RN%20(5).jpg)

-1.jpg?width=300&name=RN%20(2)-1.jpg)

.jpg?width=300&name=RN%20(5).jpg)

-1.jpg?width=300&name=RN%20(2)-1.jpg)

.jpg?width=300&name=RN%20(5).jpg)

-1.jpg?width=300&name=RN%20(2)-1.jpg)

.jpg?width=300&name=RN%20(5).jpg)

-1.jpg?width=300&name=RN%20(2)-1.jpg)

.jpg?width=300&name=RN%20(5).jpg)

Frequently Asked Questions

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

Viscosity is a measure of a fluid's resistance to flow. it affects centrifugal pumps in a variety of ways, including how much power is needed to move the fluid, how quickly the pump can move the fluid, and how efficiently the pump can move the fluid. Higher viscosity fluids require more power to move and take longer to move through the pump, whilst lower viscosity fluids require less power and can move through the pump quicker.

Anything over 25cP (centipoise) will have a significant effect on the performance of centrifugal pumps.

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Fast turnaround with pump after order sent, they also had good knowledge on what caused the pump failure.