.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

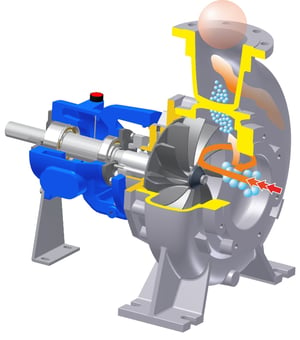

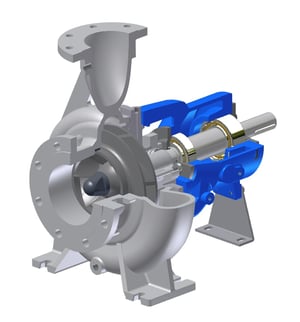

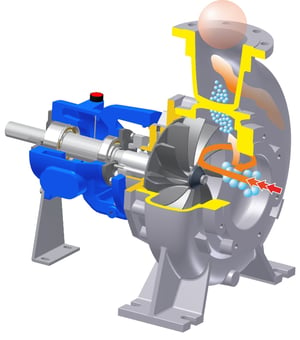

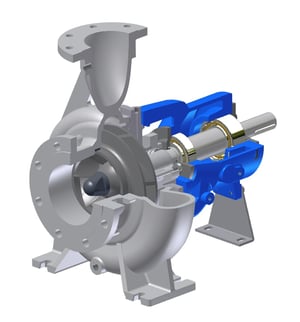

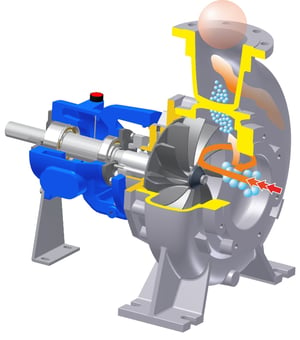

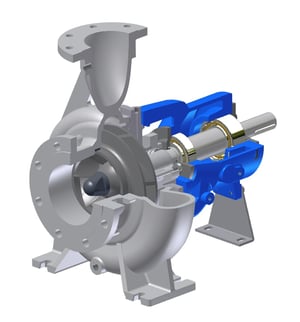

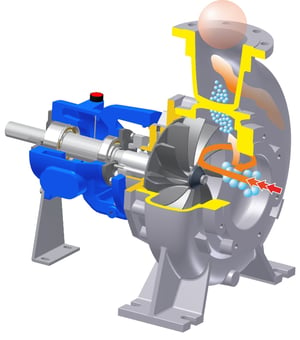

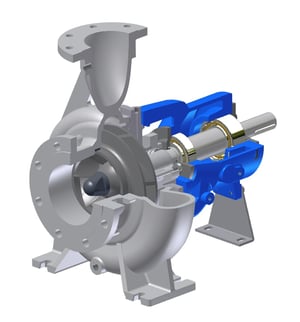

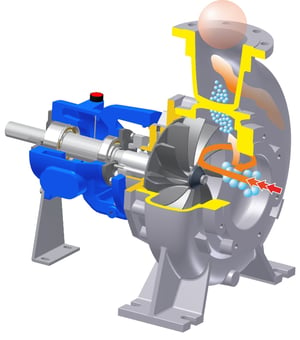

RD-RG-RC-RB Range

Metallic ISO2858 End Suction Process Pumps

Built to a heavy duty standard in a stainless steel construction, and built to ISO2858 and EN25199 which helps to ensure up to 100,000 operational hours. Minimal maintenance and high efficiency reduces downtime. This range is available with open/closed or vortex impeller options.

The RD-RG-RC-RB ranges can handle aggressive and inorganic liquids in the chemical & petrochemical industries. They are also used in sea water desalination plants, absorption equipment in environmental engineering, power stations, steel industry and hot water distribution.

.png?width=300&name=RD-RG-RC-RB%20(2).png)

FLEXIBILITY

Because of the modularity of components, either the open or closed impeller can be fitted, and with 15 different seal types. The flexibility of using one pump type for various applications reduces the cost of keeping strategic spares in stock.

This range comes with a choice of impeller designs to best fit your application. The open impeller and vortex impeller are suitable for aggressive liquids with suspended solids and high viscosities. The vortex impeller option features a recessed impeller, meaning over 60% of the liquid does not come into contact with the impeller, minimising risk of clogging.

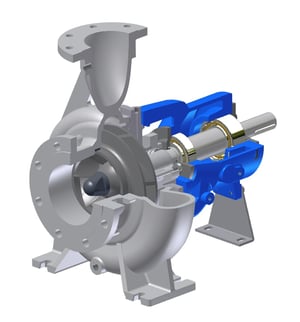

MODULAR DESIGN

The RD-RG-RC-RB range comes in three modular designs (close coupled, lantern and long coupled with base plate). The lantern bracket execution avoids any potential issues related to misalignment between the pump and motor.

The same bearing housing can be used for pumps with open, channel, closed or vortex impellers. Built according to EN25199 ensures minimal shaft deflection and over 100,000 hours of operation.

EXCLUSIVE UK DISTRIBUTOR

We’re thrilled to announce a new chapter in our partnership with Salvatore Robuschi Pumps! After more than 12 successful years of supplying their pumps under the Crest Pumps name, we are now proud to become the exclusive UK distributor for Salvatore Robuschi’s renowned range of industrial pumps.

This marks an exciting transition as we now promote these high-quality products exclusively under the SR Pumps brand. This new agreement marks a shift to promoting the products exclusively as SR pumps, aligning with our commitment to transparency, quality, and customer trust.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

The RD-RG-RC-RB range comes in three modular designs (close coupled, lantern and long coupled with base plate).

The lantern bracket execution avoids potential issues related to misalignment between the pump and motor.

How much are your pumps REALLY costing you?

Try our BPMA approved Life Cycle Cost calculator to help work out how much you could save... Upfront prices are just the beginning!

.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

.webp?width=300&name=RB%20ultrafiltration%20(3).webp)

Technical Specification

| Model | SUCTION / DISCHARGE (mm*mm) |

SPEED (rpm) |

RATED CAPACITY (m3/hr) |

RATED HEAD (m) |

MAX CAPACITY (m3/hr) |

MAX HEAD (m) |

MOTOR OUTPUT (Kw) |

BEST EFFICIENCY (%) |

| 50-32-160 | 50*32 | 2900 | 15 | 34 | 20 | 40 | 4 | 53 |

| 50-32-200 | 50*32 | 2900 | 16 | 53 | 18 | 60 | 7.5 | 50 |

| 65-40-160 | 65*40 | 2900 | 26 | 33 | 40 | 40 | 5.5 | 60 |

| 65-40-200 | 65*40 | 2900 | 24 | 52 | 38 | 60 | 9.2 | 64 |

|

80-50-160 |

80*50 |

2900 |

54 | 31 | 70 | 38 | 9.2 | 73 |

|

80-50-200 |

80*50 |

2900 |

56 | 51 | 70 | 60 | 15 | 66 |

|

80-50-250 |

80*50 |

2900 |

54 | 78 | 75 | 100 | 30 | 50 |

|

100-65-160 |

100*65 |

2900 |

80 | 31 | 130 | 40 | 15 | 69 |

|

100-65-200 |

100*65 |

2900 |

96 | 51 | 140 | 60 | 22 | 71 |

|

100-65-250 |

100*65 |

2900 |

96 | 80 | 160 | 94 | 45 | 65 |

|

100-65-310 |

100*65 |

2900 |

108 | 124 | 150 | 144 | 75 | 59 |

|

125-80-160 |

125*80 |

2900 |

132 | 30 | 180 | 37 | 18.5 | 73 |

|

125-80-200 |

125*80 |

2900 |

160 | 52 | 270 | 60 | 45 | 77 |

|

125-80-250 |

125*80 |

2900 |

180 | 80 | 240 | 94 | 75 | 73 |

|

125-80-310 |

125*80 |

2900 |

180 | 124 | 250 | 144 | 110 | 67 |

|

125-100-200 |

125*100 |

2900 |

270 | 55 | 350 | 62 | 55 | 78 |

|

125-100-250 |

125*100 |

2900 |

240 | 78 | 370 | 92 | 90 | 74 |

|

125-100-310 |

125*100 |

2900 |

240 | 128 | 320 | 144 | 160 | 73 |

|

125-100-400 |

125*100 |

1450 |

170 | 53 | 220 | 60 | 45 | 68 |

|

150-125-250 |

150*125 |

2900 |

440 | 78 | 560 | 94 | 160 | 85 |

|

150-125-310 |

150*125 |

1450 |

210 | 30 | 300 | 35 | 30 | 76 |

|

150-125-400 |

150*125 |

1450 |

220 | 54 | 290 | 58 | 55 | 71 |

|

200-150-310 |

200*150 |

1450 |

420 | 26 | 640 | 33 | 45 | 79 |

|

200-150-350 |

200*150 |

1450 |

430 | 38 | 680 | 46 | 75 | 81 |

|

250-200-350 |

250*200 |

1450 |

640 | 33 | 1050 | 43 | 90 | 79 |

|

250-200-450 |

250*200 |

1450 |

920 | 55 | 1200 | 72 | 200 | 77 |

|

300-250-350 |

300*250 |

1450 |

920 | 31 | 1350 | 40 | 110 | 79 |

|

300-250-450 |

300*250 |

1450 |

1200 | 48 | 1600 | 65 | 200 | 79 |

|

350-300-450 |

300*250 |

1450 |

1700 | 49 | 2400 | 62 | 315 | 83 |

Frequently Asked Questions

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

Chemical pumps work by using a combination of force and suction to move liquid or gas from one location to another. The pump is driven by an electric motor or other power source, and the force of the motor is used to move the liquid or gas through the pump. The pump then uses suction to draw the liquid or gas into the pump and then expel it out the other end. This process if repeated until the desired pressure and flow rate is achieved.

There are many types of chemical pumps including centrifugal and diaphragm pumps but what they have in common is the materials of construction that need to be resistant to the pumped medium. Plaastics and rubbers are common choices but also exotic metals, ceramic and even glass may be selected according to their suitability.

Viscosity is a measure of a fluid's resistance to flow. It affects centrifugal pumps in a variety of ways, including how much power is needed to move the fluid, how quickly the pump can move the fluid, and how efficiently the pump can move the fluid. Higher viscosity fluids require more power to move and take longer to move through the pump, whilst lower viscosity fluids require less power and can move through the pump quicker.

Anything over 25cP (centipoise) will have a significant effect on the performance of centrifugal pumps.

- Firstly, and most importantly : read through the manufacturer's installation and operation manual.

- Ensure that the pump is running in the correct rotation with a flick test (quickly on and off.)

- Open the suction valve and flood the pump.

- Close, or partially close the discharge valve, depending upon operating conditions.

- Open any cooling or recirculation lines, including any seal flush or system.

- Start the pump drive.

- Slowly open the discharge valve until the pump reaches the desired flow.

- Check the discharge pressure gauge to ensure the pump is operating within its parameters.

- Do not operate the pump below its minimum flow requirements or above the maximum recommended flow rate.

Centrifugal pumps are not inherently self-priming and need to have a sufficiently flooded suction to work efficiently. They can be made to self-prime by utilising an integrally designed casing that recirculates liquid around the pump until all air in the suction line is evacuated or by installing a priming chamber on the suction side of the pump. This chamber is initially filled with liquid,when the pump starts this liquid is evacuated causing a vacuum in the suction line that draws liquid into the chamber and then the pump. It is important to always consult the manufacturer who will advice on maximum suction lifts.

A mechanically sealed pump is a type of pump that uses a mechanical seal to prevent fluid leakage where the pump shaft passes through the casing. The mechanical seal consists of two flat, precision machined surfaces – one rotating with the shaft and the other stationary – pressed together by a spring or hydraulic force to create a tight seal. A thin film of fluid between these faces provides lubrication and prevents wear.

Running dry occurs when a pump operated without sufficient liquid in the system. Most pumps rely on the fluid they move for lubrication and cooling, so running dry can cause overheating, excessive wear, and serious damage to internal components like seals, bearings and impellers.

Certain pump types, such as centrifugal pumps, are particularly vulnerable to dry running because they require fluid to create suction and maintain efficiency. On the other hand, some designs, like peristaltic pumps and diaphragm pumps, can handle dry running for short periods without significant damage.

To prevent dry running, many systems use dry-run protection sensors, such as flow switches, pressure sensors, or thermal shutdown mechanisms, which automatically stop the pump if no liquid is detected. Proper system design, including ensuring adequate priming and suction conditions, is also essential to avoid dry running and extend pump life.

Trusted By The Best