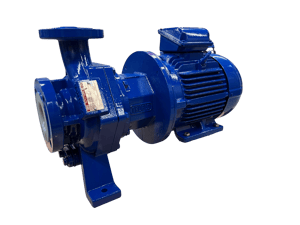

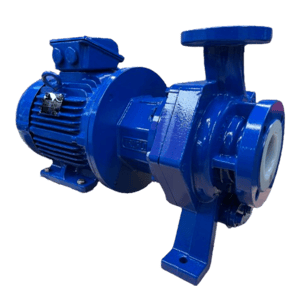

When you need a chemical pump conforming to ANSI specifications, with quick deliveries and reasonable pricing, Crest Pumps can exclusively offer you the USA made Truflo TNP ANSI mag drive non-metallic pump range.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Upfront costs are just the beginning—did you know energy and maintenance make up most of a pump’s lifetime cost? A Life Cycle Cost (LCC) analysis breaks down these expenses, showing how small changes can lead to big savings in efficiency, running costs, and carbon footprint.

Stop replacing pumps and start investing in performance.

1. Drain - Our casing drain is a standard feature that allows for easy and safe removal of chemicals in the casing if required.

2. Casing - The top discharge ANSI configurations allows for maximum pump interchangeability. Our unique ETFE roto-moulding process promotes equal delivery of liner material throughout casing for improved corrosion resistance and longer life.

3. Shaft Support - One piece construction that is easily removed.

4. Mouth ring - Easily removable for quick field replacement. The unique design allows for handling of a variety of chemicals and specific heat parameter. Available in SiC.

5. Impeller/Inner magnet - Our unique ETFE injection moulding process allows us to ensure high quality, stronger, and more chemically resistant impellers. Our process has eliminated welding that can contribute to premature impeller failure.

6. Main Bushing - Our large, one piece, high performance bushing is grooved to allow for field and particle flow through the pump.

7. Shaft - This non-rotating design allows for ease and installation and maintenance. This shaft is oversized to handle a variety of pump requirements.

8. O-ring - Available in VITON Teflon encapsulated VITON or EPDM.

9. Rear containment shell - Our shell is an injection moulded fluoropolymer with a composite encapsulation. This design offers some of the industries strongest containment shell burst pressure resistance.

10. Rear Casing Support

11. Outer magnet - Our rare earth magnets make it possible to run the pump at rated torque throughout the temperature range without having to use special motors or starters. Our magnets are fully encapsulated for superior protection from corrosion.

12. Bracket - Designed to mate with several motor sizes. In a close - couple configuration, the driver will accept either a NEMA C-face or an IEC motor.

Frequently Asked Questions

Magnetic drive pumps are used in a wide variety of applications, including chemical processing, water treatment, and metal finishing. They are designed to provide a reliable and efficient solution for transferring corrosive and hazardous liquids. The pumps are constructed with a non-metallic construction, making them ideal for use in highly corrosive and hazardous environments.

Magnetic drive pumps are centrifugal pumps that use a magnetic coupling to transmit power from the motor to the impeller. The drive magnet is mounted on the motor shaft that will connect by magnetic force to driven magnets contained within the pump. This type of pump is ideal for applications where leakage or contamination of the pumped fluid is a concern, as there is no mechanical seal or shaft seal to fail.

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

- Check the pump regularly for signs of wear and tear.

- Ensure the pump is properly lubricated.

- Check the bearings for any signs of wear or damage.

- Ensure that the pump is properly aligned with the drive motor.

- Check the temperature of the pump and ensure it does not exceed the recommended levels.

- Ensure that the pump is running at the correct speed.

Trusted By The Best