PTCXPUMP Range

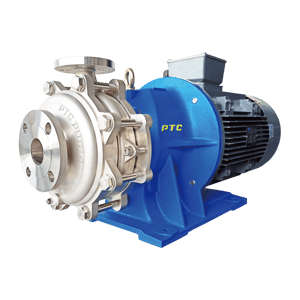

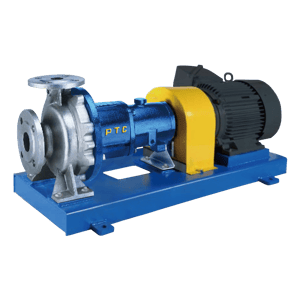

Stainless Steel Mag Drive Pumps

The PTCXPUMP series of mag drive pumps are manufactured from AISI 316L stainless steel and available with closed, open and peripheral impeller designs. ATEX certified and high efficiency designs and temperature up to 280°C. These pumps are commonly used in Chemical, Semiconductor, Carbon Capture, Wind Turbine and Hydrogen industries and more.

Explore the PTCXPUMP Range

Flow <81 L/Min Head <30m

The smallest of the range, ideal for small laboratories

Download our datasheet

Flow <850 L/Min Head <68m

Medium Capacity, ideal for chemical fluid transfer

Download our datasheet

Flow <2001 L/Min Head <132m

Ideal for large flow, higher head applications

Download our datasheet

Flow <450 L/Min Head 53.1m

Semi-jacketed to maintain process temperature

Download our datasheet

Flow <450 L/Min Head 63.3m

Open impeller, ideal for sludge & slurries

Download our datasheet

Flow<3200L/Min Head 220m

Largest in the series with power up to 110kW

Download our datasheet

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.

That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

The true cost of your pump

Upfront prices are just the beginning — energy and maintenance make up most of a pump’s lifetime cost. Our Lifecycle cost calculator (LCC) breaks it down, helping you compare different pump types and manufacturers to find the best solution for your needs.

.png?width=300&name=PTCX5-removebg-preview%20(1).png)

Technical Specification

| Model | PM | PS | PL | PW | |

| Frequency | 50Hz | 60Hz | 50Hz 60Hz | 50Hz 60Hz | 50Hz 60Hz |

| Max. Capacity | 81L/M | 81L/M | 850L/M 850L/M | 1904L/M 2001L/M | 49L/M 53L/M |

| Max. Total Head | 22m | 30m | 55.7m 68m | 91.3m 132m | 78m 108m |

| Suction & Discharge | 15 x 13 - 25 x 20 | 25 x 20 - 80 x 40 | 40 x 25 - 100 x 80 | 15 x 15 - 25 x 25 | |

| Temperature Range | -80°C - 280°C | -80°C - 280°C | -80°C - 280°C | -80°C - 280°C | |

| Specific Gravity | <2 | <2 | <2 | <2 | |

| Viscosity | <100mPa.s (cp) | <300mPa.s(cp) | <300mPa.s(cp) | <300mPa.s(cp) | |

| Design Pressure | 0.6MPaG (*PM2021:1.0MPaG*) | 1.0MPaG | 1.2MPaG (*PL-50X25-250LF:1.6MPaG*) | 1.6MPaG | |

| Flange Standard | R Thread Type | ANSI class 150/JIS 10K/ DIN PN16 | ANSI Class 150/ JIS 10K/ DIN PN16 | ANSI class 150 / JIS 10K / DIN PN16 | |

| Motor Output | 90W - 550W | 0.75KW - 7.5KW | 5.5KW - 18.5KW | 0.75KW - 3.7KW | |

| Pump Material | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | |

| Model | PSJ | PSO | PL2 | PC | |

| Frequency | 50Hz | 60Hz | 50Hz 60Hz | 50Hz 60Hz | 50Hz 60Hz |

| Max. Capacity | 400L/M | 450L/M | 400L/M 450L/M | 500L/M 500L/M | 2800L/M 3200L/M |

| Max. Total Head | 36.8m | 53.1m | 42.7m 61.3m | 85m 121m | 87m 220m |

| Suction & Discharge | 25 x 20 - 50 x 40 | 25 x 20 - 50 x 40 | 50 x 25 | 80 x 40 - 100 x 80 | |

| Temperature Range | -80°C - 280°C | -80°C - 280°C | -80°C - 280°C | -80°C - 280°C | |

| Specific Gravity | <2 | <2 | <2 | <2 | |

| Viscosity | <300mPa.s (cp) | <300mPa.s(cp) | <300mPa.s(cp) | <300mPa.s(cp) | |

| Design Pressure | 1.0MPaG | 1.0MPaG | 1.6MPaG | 1.6MPaG | |

| Flange Standard | ANSI class 150/ JIS 10K / DIN PN16 | ANSI class 150/JIS 10K/ DIN PN16 | ANSI Class 150/ JIS 10K/ DIN PN16 | ANSI class 150 / JIS 10K / DIN PN16 | |

| Motor Output | 0.75KW - 3.7KW | 0.75KW - 3.7KW | 11KW - 18.5KW | 22kw-75 kw 45kw-110kw | |

| Pump Material | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | SUS316L (Standard) / Alloy20 (Optional) / HAS-C equivalent (Optional) | |

Reduce Costs with Modular Design & Interchangeable Components

Frequently Asked Questions

Magnetic drive pumps are used in a wide variety of applications, including chemical processing, water treatment, and metal finishing. They are designed to provide a reliable and efficient solution for transferring corrosive and hazardous liquids. The pumps are constructed with a non-metallic construction, making them ideal for use in highly corrosive and hazardous environments.

Magnetic drive pumps are centrifugal pumps that use a magnetic coupling to transmit power from the motor to the impeller. The drive magnet is mounted on the motor shaft that will connect by magnetic force to driven magnets contained within the pump. This type of pump is ideal for applications where leakage or contamination of the pumped fluid is a concern, as there is no mechanical seal or shaft seal to fail.

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

- Check the pump regularly for signs of wear and tear.

- Ensure the pump is properly lubricated.

- Check the bearings for any signs of wear or damage.

- Ensure that the pump is properly aligned with the drive motor.

- Check the temperature of the pump and ensure it does not exceed the recommended levels.

- Ensure that the pump is running at the correct speed.

Trusted By The Best