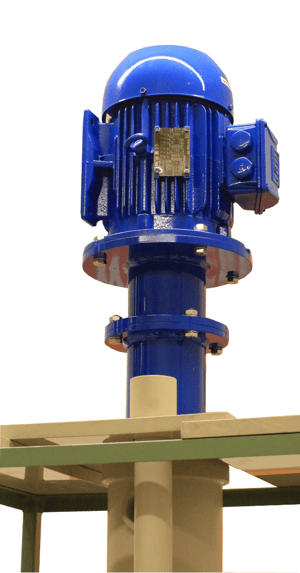

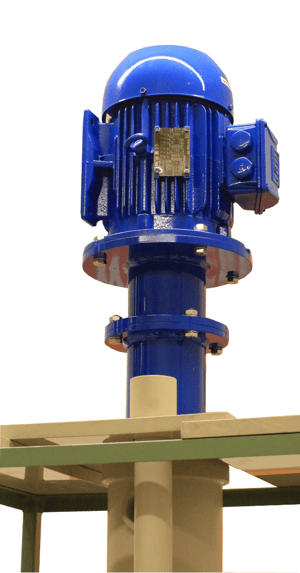

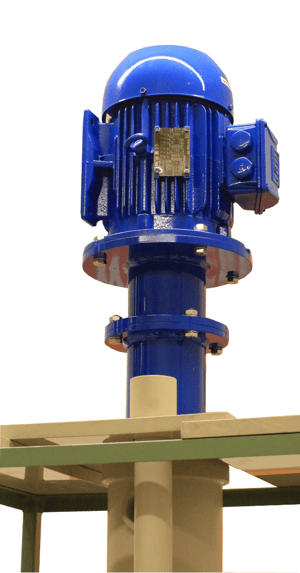

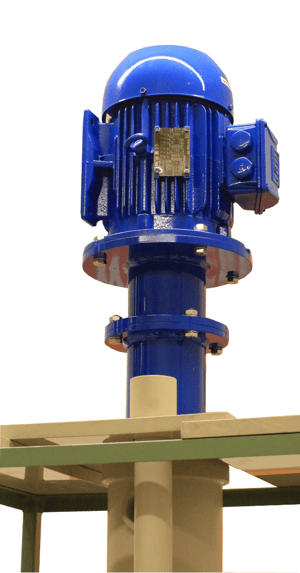

CSS Range

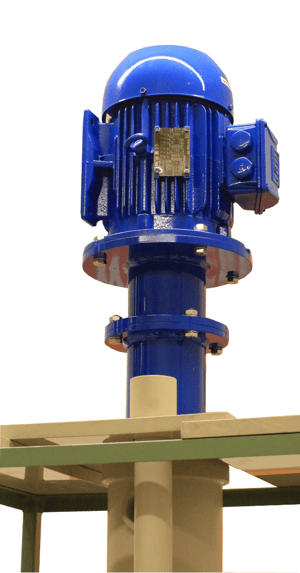

Cantilever Corrosion Resistant Sump Pump

Built with a cantilever shaft design, CSS pumps have no immersed bearings which allows the pump to run-dry indefinitely without damage. Bearings aren’t required at the bottom of the pump due to the oversized shaft which adds stability to prevent shaft whipping.

<750mm

The CSS range of vertical plastic pumps have been perfected over 40 years to combat harsh and corrosive chemicals making the CSS range ideal for applications such as sump emptying, recirculation, effluent treatment and fume scrubbers.

Every plastic vertical pump in our range is designed and manufactured in the UK so we can tailor the pump to your exact requirements – whether that be a particular column length,mounting plate shape or outlet position. Usually with very little difference in price or lead time compared to a standard pump.

The CSS range is available in polypropylene or PVDF for the ultimate corrosion resistance to harsh and acidic applications. O-rings are available in Viton, EPDM or Kalrez.

BUILT TO YOUR REQUIREMENTS

The vertical range are proven to stand the test of time offering solid performance constantly throughout the pumps lifetime. And because of their run dry capability, minimise both operational costs and maintenance costs whilst keeping your process running efficiently and reliably. To ensure that we supply you with a pump that will last in the harshest of environments, pumps are available in a variety of materials including polypropylene, PVC, PVDF and 316 stainless steel. Every plastic vertical pump in our range is designed and manufactured in the UK so we can tailor the pump to your exact requirements – whether that be a particular column length, mounting plate shape or outlet position. Usually with very little difference in price or lead time compared to a standard pump.

HEAVY DUTY

The CSS range of vertical plastic pumps have been perfected over 40 years to combat harsh and corrosive chemicals making the CSS range ideal for applications such as sump emptying, recirculation, effluent treatment and fume scrubbers. Built with a cantilever shaft design, CSS pumps have no immersed bearings which allows the pump to run-dry indefinitely without damage. Bearings aren’t required at the bottom of the pump due to the oversized shaft which adds stability to prevent shaft whipping. The CSS range is available in polypropylene, PVC, PVDF or 316 stainless steel for the ultimate corrosion resistance to harsh and acidic applications. O-rings are available in Viton, EPDM or Kalrez. The support column is fabricated and incorporates a double skinned, heavy duty tube arrangement making the CSS range of pumps exceptionally rugged and robust.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Upfront prices are just the beginning — energy and maintenance make up most of a pump’s lifetime cost. Our Lifecycle Cost Calculator (LCC) breaks it down, helping you compare different pump types and manufacturers to find the best solution for your needs.

Technical Specification

| Model | SUCTION (inches) |

DISCHARGE (inches) |

SPEED (rpm) |

RATED CAPACITY (m /hr) |

RATED HEAD (m) |

MAX CAPACITY (m /hr) |

MAX HEAD (m) |

MOTOR OUTPUT (kW) |

| CSS 20 | 1.5 | 1.25 | 2900 | 9 | 9 | 16 | 13 | 1.5 |

| CSS 30 | 2 | 1.5 | 2900 | 15 | 16 | 28 | 18 | 3 |

| CSS 35 | 2.5 | 2 | 2900 | 30 | 22 | 50 | 28 | 5.5 |

| CSS 40 | 2.5 | 2 | 2900 | 30 | 34 | 60 | 40 | 1.1 |

Frequently Asked Questions

Submersible pumps are complete units, including the motor, and the whole can be totally submerged whereas immersible pumps are mounted in vertical position with the motor above the liquid and the pump end extended below the liquid level.

A vertical immersible pump operates with its pump end submerged in the fluid while the motor remains above the liquid level. The pump uses an impeller to draw fluid up through the pump column and discharge it at the surface. This design prevents motor exposure to harsh fluids, making it ideal for handling corrosive, abrasive, or high-temperature liquids in industries like chemical processing and wastewater treatment.

Vertical immersible pumps offer several benefits, including space-saving design, as they require a smaller footprint than horizontal pumps. They prevent motor exposure to corrosive or hazardous fluids by keeping the motor above the liquid level. These pumps also provide high efficiency and reliability, with minimal risk

of leaks due to their seal-less or semi-sealed designs. Additionally, they are easy to maintain, as the motor and key components remain accessible without needing to drain the tank or sump

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Crest have been my preferred supplier of pumps for over 30 years, and have always given me good advice, a quality product and excellent service.