Cantilever Range

Metallic Cantilever Immersible Sump Pump

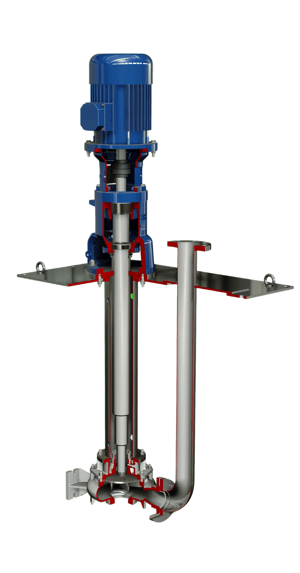

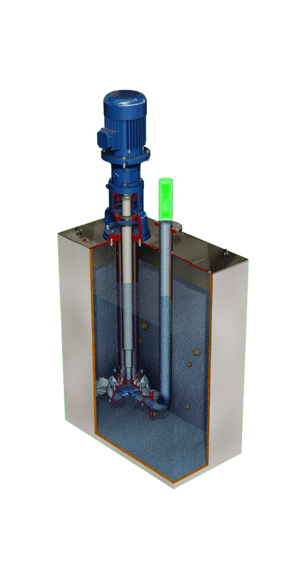

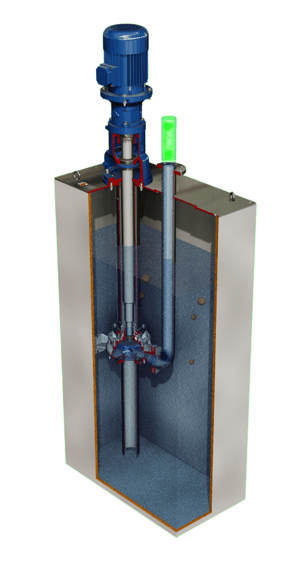

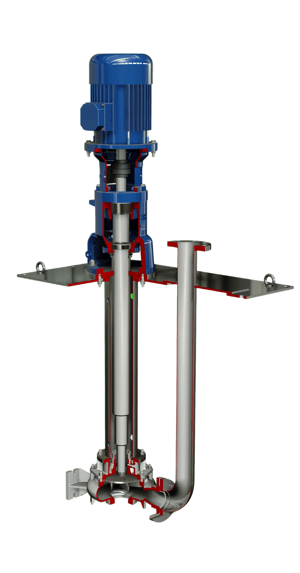

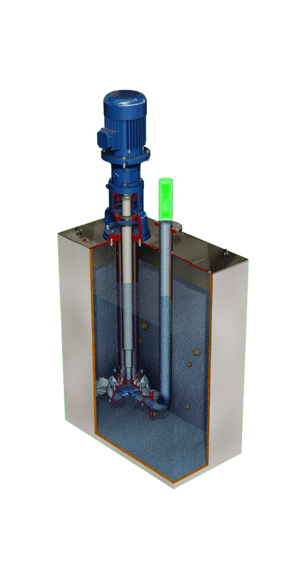

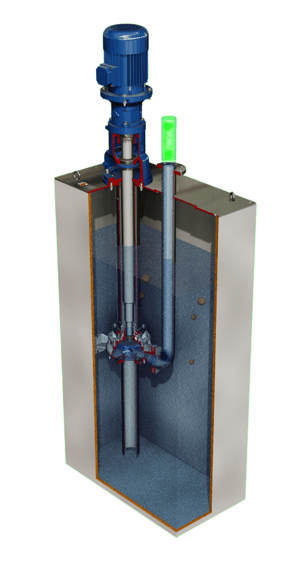

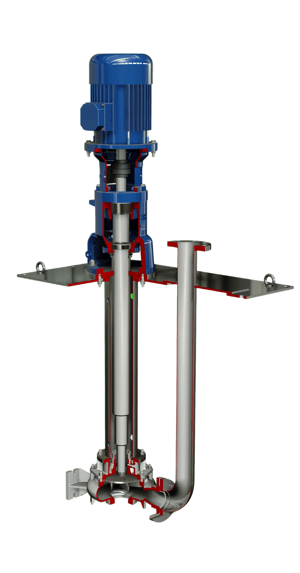

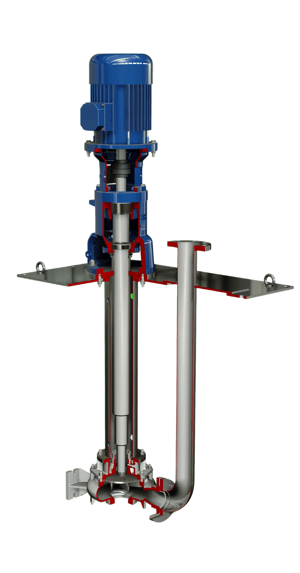

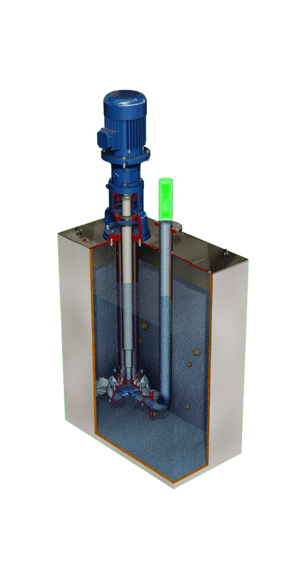

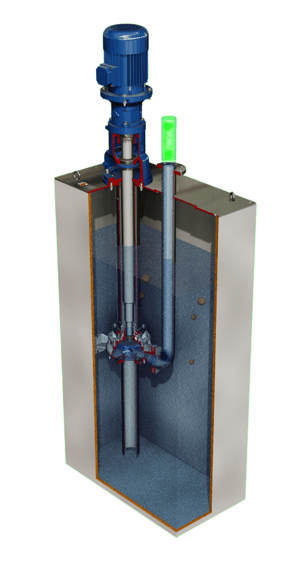

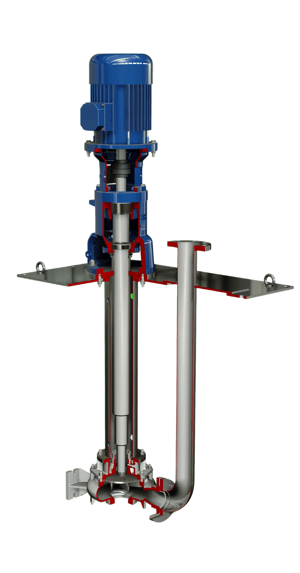

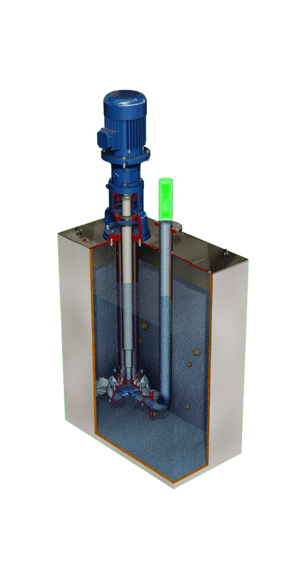

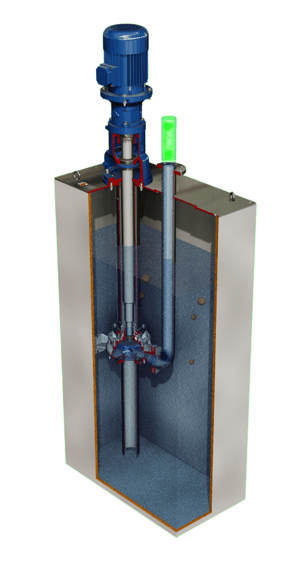

The Cantilever range of vertical immersible centrifugal pumps is designed for exceptional durability in aggressive and corrosive environments. Engineered with a bearing-free cantilever shaft (300mm to 1500mm), these pumps offer complete reliability by running dry without damage, making them ideal for demanding applications.

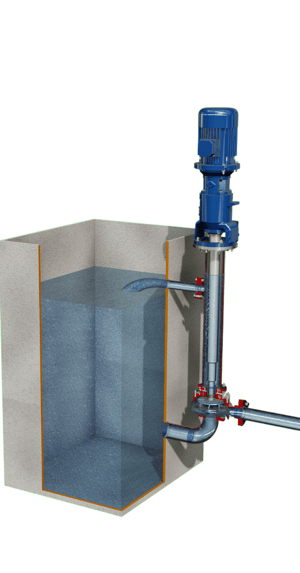

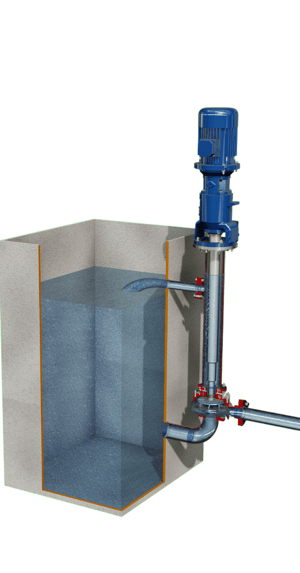

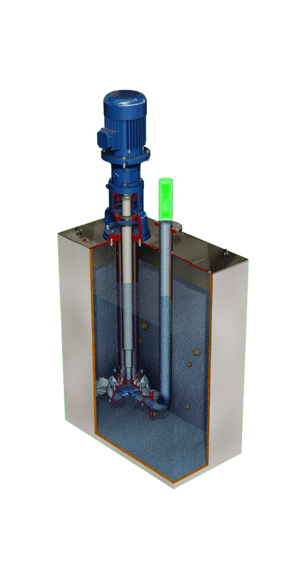

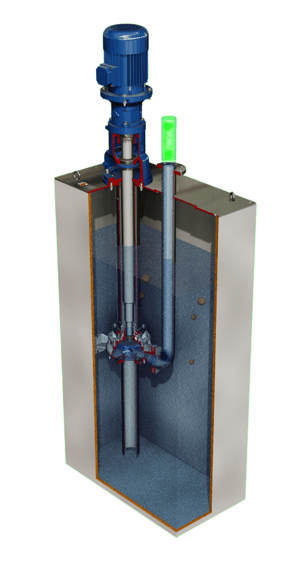

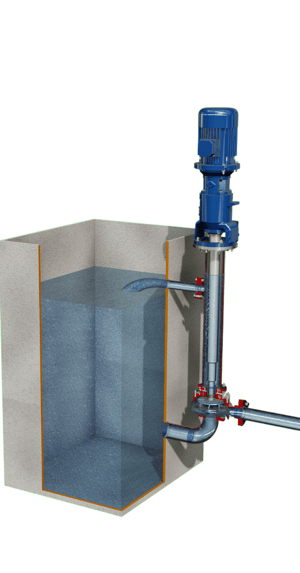

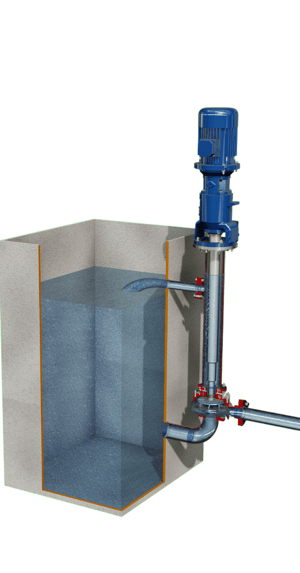

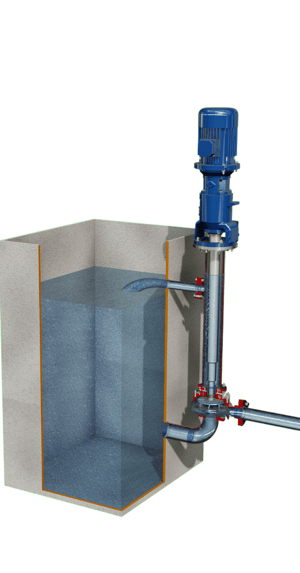

With a customizable design, we tailor each pump to your exact specifications—offering flexibility in column length, materials of construction, impeller types, mounting plate size, and discharge pipe location. Suitable for both new and replacement applications, these pumps can be internally or externally mounted and handle clean or solids-laden liquids at temperatures up to 500°C.

Unlike conventional designs, our Cantilever pumps feature an immersed pump body with a motor mounted above the corrosive zone, ensuring maximum protection. Oversized heavy-duty ball bearings, located above the mounting plate and sealed against contamination, further enhance longevity and reliability. With no bearings, seals, or bushings in the liquid, the risk of failure is significantly reduced, resulting in lower maintenance costs and long-term operational efficiency.

For additional customization, we offer suction strainers and suction extensions. This makes our Cantilever pumps ideal for a wide range of applications, including: sludges & slurries, drainage & oily water sumps and tank transfer.

A key feature of the Cantilever range is the ability to pump liquids with high temperatures and the ability to run dry without causing damage to the pump, due to no bearings or bushings being submerged.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

EXCLUSIVE UK DISTRIBUTOR

We’re thrilled to announce a new chapter in our partnership with Salvatore Robuschi Pumps! After more than 12 successful years of supplying their pumps under the Crest Pumps name, we are now proud to become the exclusive UK distributor for Salvatore Robuschi’s renowned range of industrial pumps.

This marks an exciting transition as we now promote these high-quality products exclusively under the SR Pumps brand. This new agreement marks a shift to promoting the products exclusively as SR pumps, aligning with our commitment to transparency, quality, and customer trust.

Built to outlast and outperform

Selecting the right pump goes beyond just initial cost—energy and maintenance make up the majority of a pump’s lifetime expenses. With our Life Cycle Cost (LCC) calculator, you can compare different pump options and see the true cost of ownership, helping you make the most efficient and cost-effective choice.

.jpg?width=300&name=cantilever%20Kemira%20(2).jpg)

.jpg?width=300&name=cantilever%20for%20beer%20Estrella%20Dam%20(2).jpg)

.jpg?width=300&name=cantilever%20(2).jpg)

.jpg?width=300&name=cantilever%20Kemira%20(2).jpg)

.jpg?width=300&name=cantilever%20for%20beer%20Estrella%20Dam%20(2).jpg)

.jpg?width=300&name=cantilever%20(2).jpg)

.jpg?width=300&name=cantilever%20Kemira%20(2).jpg)

.jpg?width=300&name=cantilever%20for%20beer%20Estrella%20Dam%20(2).jpg)

.jpg?width=300&name=cantilever%20(2).jpg)

.jpg?width=300&name=cantilever%20Kemira%20(2).jpg)

.jpg?width=300&name=cantilever%20for%20beer%20Estrella%20Dam%20(2).jpg)

.jpg?width=300&name=cantilever%20(2).jpg)

.jpg?width=300&name=cantilever%20Kemira%20(2).jpg)

.jpg?width=300&name=cantilever%20for%20beer%20Estrella%20Dam%20(2).jpg)

.jpg?width=300&name=cantilever%20(2).jpg)

Technical Specification

| Model | SUCTION / DISCHARGE (mm*mm) |

SPEED (rpm) |

RATED CAPACITY (m /hr) |

RATED HEAD (m) |

MAX CAPACITY (m /hr) |

MAX HEAD (m) |

MOTOR OUTPUT (Kw) |

BEST EFFICIENCY (%) |

| 50-32-160 | 50*32 | 2900 | 32 | 33 | 40 | 41 | 7.5 | 37 |

| 50-32-200 | 50*32 | 2900 | 36 | 51 | 40 | 63 | 15 | 35 |

| 65-50-160 | 65*50 | 2900 | 64 | 36 | 75 | 42 | 15 | 48 |

| 65-50-200 | 65*50 | 2900 | 58 | 52 | 75 | 60 | 18.5 | 46 |

| 65-50-250 | 65*50 | 1450 | 64 | 21 | 90 | 25 | 11 | 50 |

| 80-65-200 | 80*65 | 2900 | 78 | 52 | 100 | 60 | 22 | 51 |

| 100-80-200 | 100*80 | 1450 | 76 | 11 | 140 | 13 | 7.5 | 52 |

| 100-80-250 | 100*80 | 1450 | 120 | 24 | 150 | 27 | 15 | 57 |

| 100-80-310 | 100*80 | 1450 | 210 | 34 | 270 | 38 | 45 | 53 |

| 125-100-250 | 125*100 | 1450 | 190 | 21 | 250 | 22 | 22 | 54 |

| 150-125-250 | 150*125 | 1450 | 270 | 18 | 450 | 20 | 45 | 48 |

| 150-125-310 | 150*125 | 1450 | 320 | 32 | 400 | 37 | 55 | 54 |

Frequently Asked Questions

Submersible pumps are complete units, including the motor, and the whole can be totally submerged whereas immersible pumps are mounted in vertical position with the motor above the liquid and the pump end extended below the liquid level.

A vertical immersible pump operates with its pump end submerged in the fluid while the motor remains above the liquid level. The pump uses an impeller to draw fluid up through the pump column and discharge it at the surface. This design prevents motor exposure to harsh fluids, making it ideal for handling corrosive, abrasive, or high-temperature liquids in industries like chemical processing and wastewater treatment.

Vertical immersible pumps offer several benefits, including space-saving design, as they require a smaller footprint than horizontal pumps. They prevent motor exposure to corrosive or hazardous fluids by keeping the motor above the liquid level. These pumps also provide high efficiency and reliability, with minimal risk

of leaks due to their seal-less or semi-sealed designs. Additionally, they are easy to maintain, as the motor and key components remain accessible without needing to drain the tank or sump

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

I would recommend Crest Pumps highly as from my experience all enquiries and any issues are dealt with promptly and professionally.