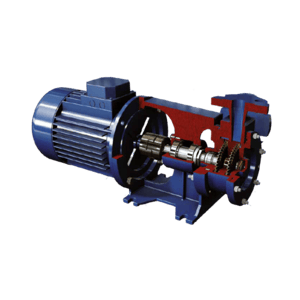

High Pressure double stage centrifugal pumps

Double-stage centrifugal pumps with peripheral impellers (TS) feature discharge sizes of DN 25. RAM pumps are designed to handle clean liquids without suspended solids. They are commonly used for boiler feed applications, flotation plants in wastewater treatment, and any situation requiring low capacity combined with high pressure.

6.3 m3/h

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Discover the significant savings you can achieve and explore the potential financial benefits that await you.

Frequently Asked Questions

Multistage pumps are centrifugal pumps (often vertically mounted) consisting of a series of impellers and casings mounted one after the other in series so that the discharge of one casing enters directly into the suction of the next. As each stage will only elevate the pressure by a set amount, a multistage pump will increase the pressure in each stage so that a final high pressure comes from the last stage.

For instance, let’s take an example of a 10-stage vertical pump, and each stage can increase the pressure by 0.5 bar. Liquid enters the first stage at atmospheric pressure and is elevated by 0.5 bar to enter the second stage, this then increased the pressure by 0.5 bar to enter the third stage at 1 bar. This is repeated until the liquid exits the final stage at 5 bar pressure.

It’s important to realise that only the pressure is increased and not the flow rate as the stages is mounted in series. To increase the flow rate, you would need to mount the pumps in parallel.

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Crest answer our questions promptly, and always help us out when we need to source items quickly!