Industrial process pumps in accordance with API 610

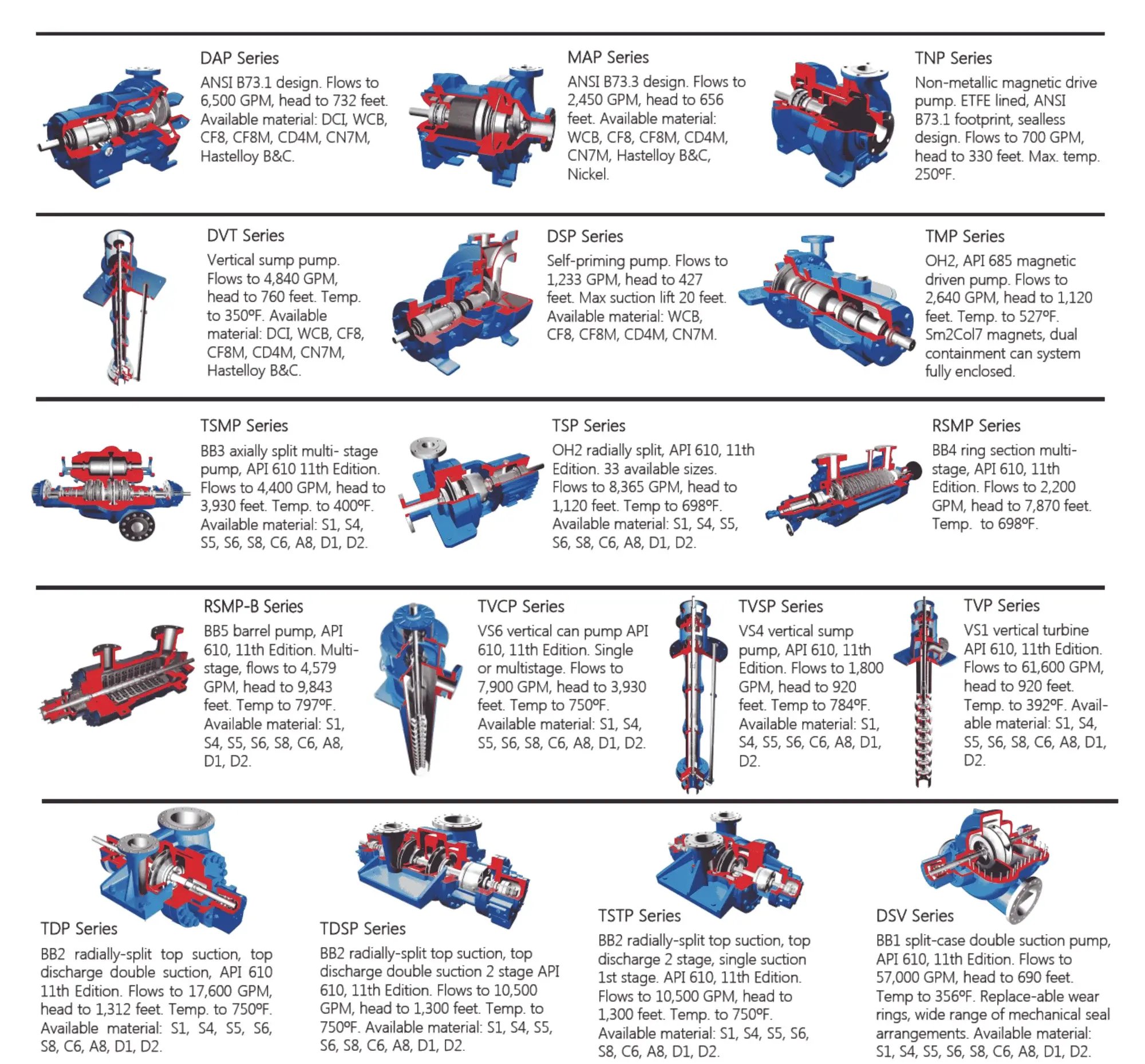

USA made Truflo offer a comprehensive range of industrial API process pumps designed to meet the rigorous standards of API 610 11th Edition and API 685 2nd Edition.

Engineered for optimal performance in high-temperature and high-pressure environments, ensuring reliability across various applications.

Need expert advice?

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.

That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Upfront costs are just the beginning—did you know energy and maintenance make up most of a pump’s lifetime cost? A Life Cycle Cost (LCC) analysis breaks down these expenses, showing how small changes can lead to big savings in efficiency, running costs, and carbon footprint.

-(modified)_Page_1_Image_0006.jpg?width=300&name=TRUFLO---Line-Card-(HiRes)-(modified)_Page_1_Image_0006.jpg)

Frequently Asked Questions

Lifecycle Cost (LCC) Analysis is a method used to determine the total cost of ownership of a pump over its entire operational lifespan. Instead of focusing solely on the initial purchase price, LCC considers all costs associated with the pump, including installation, energy consumption, maintenance, repairs, downtime, and disposal or replacement. By evaluating these factors, businesses can make informed decisions that minimize overall expenses and improve efficiency.

For pumps, energy costs typically make up the largest portion of LCC, often exceeding the initial purchase price. Other significant factors include maintenance and repair costs, which can increase if a pump operates outside its Best Efficiency Point (BEP) or is not properly maintained. By selecting energy-efficient models, implementing predictive maintenance, and considering materials that extend pump life, businesses can reduce LCC and achieve long-term cost savings while improving reliability and performance.

Best Efficiency Point (BEP) is the operating point at which a pump runs at its highest efficiency while minimizing energy consumption and wear. It represents the optimal balance between flow rate and head, ensuring the pump delivers the best performance with the least amount of stress on its components.

Operating a pump away from its BEP—either too far to the left (low flow, high head) or too far to the right (high flow, low head)—can lead to problems such as cavitation, excessive vibration, increased energy costs, and premature wear on bearings and seals. Proper pump selection and system design aim to keep the pump as close to its BEP as possible to maximize efficiency, reduce maintenance costs, and extend pump life.

NPSHa stands for Nett Positive Suction AVAILABLE and NPSHr stands for Nett Positive Suction Head REQUIRED.

Now, what is the difference between NPSHa and NPSHr? Well, firstly NPSH is a measure of the pressure experienced by the fluid at the suction of the pump. This is always quoted in metres (or feet) rather than as a pressure because head is a fluid independent property. Keep in mind that a pump will always lift liquid to the same height regardless of the fluid's respective densities.

NPSHa (available) is a property of the system and is calculated by the system designer giving a value of the pressure on the suction side of the pump.

NPSHr (required) is a property of the pump. This is calculated by the manufacturer as the point where cavitation occurs. It is good practice to have a safety margin between 0.5m and 1m.

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Crest are very helpful and knowledgeable on different applications; I would recommend Crest Pumps to anyone.