The AMXi range of magnetic drive pumps are designed to provide you with a long service life and minimal running costs. Operating at over 70% efficiency, AMXi pumps can be relied upon to work in the toughest of conditions including high corrosion, temperature and ATEX Zones 1 and 2.

REDUCED LIFE CYCLE COST

The patented run dry technology built into the AMXi helps protect your pumps from a failure in the process. Most mechanically sealed pumps will fail when run dry, causing dangerous leakages and costly clean up bills as a result. However with the AMXi, the pump can run dry for a number of hours alleviating process problems and avoiding damage to the pump.

HIGH EFFICIENCY DESIGN

The geometry of the impeller and casing are generated through hydraulic design programmes. Whilst taking into account the fluid dynamics, hydraulic loss is minimised and pump efficiency maximised. The AMXi range operates at over 70% efficiency. Lower electricity costs also come from the use of high efficiency IE3 motors (where available). We also trim the impeller diameter to your required duty point, increasing process efficiency. Inverters are also available to achieve the ultimate efficiency in your system.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

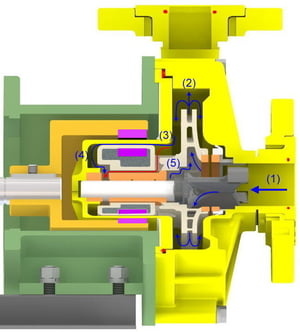

Under normal conditions, pumped liquid cools and lubricates the pump. But when starved of liquid, heat from friction can cause damage.

Crest Assoma’s Mag Drive range prevents this with a patented auxiliary circulation channel, cooling the bearing without reducing pump efficiency—even in dry-run scenarios.

For a smarter, more cost-effective solution, use our Life Cycle Cost (LCC) analysis to compare pump options and find the most efficient choice.

Technical Specification

| Model | Suction (mm) | Discharge (mm) | Speed (rpm) | Rated Capacity (L/min) | Rated Head (m) | MAX CAPACITY (L/min) |

MAX HEAD (m) |

MOTOR OUTPUT (kW) |

BEST EFF. (%) |

| AMX 420 | 40 | 25 | 2900 | 100 | 10.9 | 250 | 12.3 | 0.4 | 70 |

| AMX 441 | 40 | 40 | 2900 | 150 | 15.6 | 350 | 19.0 | 0.75 | 70 |

| AMX 542 | 50 | 40 | 2900 | 200 | 20.6 | 450 | 24.4 | 1.5 | 70 |

| AMX 542H | 50 | 40 | 2900 | 100 | 25.8 | 300 | 27.6 | 1.5 | 70 |

| AMX 543 | 50 | 40 | 2900 | 250 | 25.8 | 500 | 30.6 | 2.2 | 70 |

| AMX 543H | 40 | 40 | 2900 | 150 | 31.8 | 350 | 34.2 | 2.2 | 70 |

| AMX 545 | 50 | 50 | 2900 | 250 | 30.2 | 500 | 35.0 | 4.0 | 70 |

| AMX 653 | 65 | 50 | 2900 | 450 | 17.0 | 700 | 20.0 | 2.2 | 70 |

| AMX 655 | 65 | 50 | 2900 | 500 | 25.0 | 800 | 27.6 | 4.0 | 70 |

Frequently Asked Questions

Magnetic drive pumps are used in a wide variety of applications, including chemical processing, water treatment, and metal finishing. They are designed to provide a reliable and efficient solution for transferring corrosive and hazardous liquids. The pumps are constructed with a non-metallic construction, making them ideal for use in highly corrosive and hazardous environments.

Magnetic drive pumps are centrifugal pumps that use a magnetic coupling to transmit power from the motor to the impeller. The drive magnet is mounted on the motor shaft that will connect by magnetic force to driven magnets contained within the pump. This type of pump is ideal for applications where leakage or contamination of the pumped fluid is a concern, as there is no mechanical seal or shaft seal to fail.

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

- Check the pump regularly for signs of wear and tear.

- Ensure the pump is properly lubricated.

- Check the bearings for any signs of wear or damage.

- Ensure that the pump is properly aligned with the drive motor.

- Check the temperature of the pump and ensure it does not exceed the recommended levels.

- Ensure that the pump is running at the correct speed.

Trusted By The Best