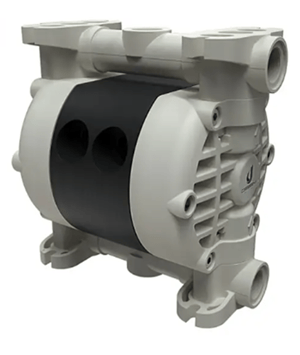

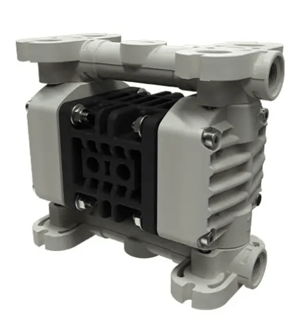

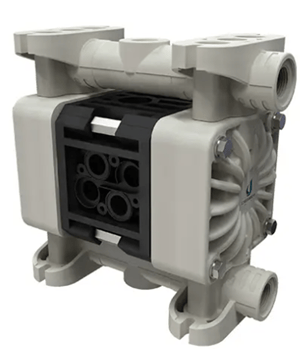

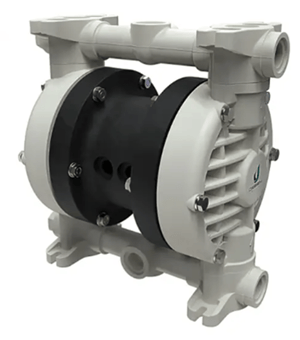

Remote Controlled Double Diaphragm Pumps

The Crest Debem double diaphragm pumps of the RC line have been designed for all applications that require the pump to be controlled remotely or directly by the machine on which the pump is installed and are always operated with compressed air. They are ideal for pumping liquids with high viscosity, even if containing suspended solids.

All the remote controlled range are ATEX - IECEx certified, constructed in Polypropylene or PVDF in the plastic version or in aluminum or AISI 316 L for the metal versions. The vast range of materials available for the parts in contact with the fluid, such as pump casings and manifolds, diaphragms, balls, ball seats and o-rings, makes them compatible with any type of fluid present on the market.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Explore our RC RANGE

Find out the true cost of your pump

Upfront prices are just the beginning — energy and maintenance make up most of a pump’s lifetime cost. Our Lifecycle Cost (LCC) calculator breaks it down, helping you compare different pump types and manufacturers to find the best solution for your needs.

Technical Specification

| S-MBOX | S-CUBIC | S-MICRO | S-BOXER7 | S-BOXER15 | |

| Suction / delivery connections | BSPP 1/4" f | G 3/8" f | G 1/2" f | BSPP 1/4" f | BSPP 3/8" f |

| Air Fitting | BSPP 1/8 "f | G 3/8" f | G 1/4" f | BSPP 1/8" f | BSPP 3/8" f |

| Max. Flow rate | 6 l/min | 17 l/min | 35 l/min | 9 l/min | 17 l/min |

| Max supply air pressure | 8 bar | 8 bar | 8 bar | 8 bar | 8 bar |

| Max. negative suction head - dry running ** | 3m | 3m | 4m | 4m | 3m |

| Max negative suction head - pump primed | 9.5m | 9.5m | 9.5m | 9.5m | 9.5m |

| Diameter max suspended solids | 0mm | 0.5mm | 2mm | 0.5mm | 0.5mm |

| Noise Level | 60 dB | 65 dB | 65 dB | 65 dB | 65 dB |

| Volume Stroke | 3.2cc | 10.3 cc | 30 cc | 3.2 cc | 10.3 cc |

| S-BOXER50 | S-BOXER81 | S-MINI | S-BOXER100 | |

| Suction / delivery connections | G 1/2" f o DN 15 | BSPP 1" f | G 1/2" f o DN 15 | G 1" f o DN 25 |

| Air Fitting | G 3/8" f | BSPP 3/8" f | G 3/8" f | G 3/8" f |

| Max. Flow rate | 60 l/min | 110 l/min | 60 l/min | 160 l/min |

| Max supply air pressure | 8 bar | 8 bar | 8 bar | 8 bar |

| Max. negative suction head - dry running ** | 4m | 4m | 4m | 4m |

| Max negative suction head - pump primed | 9.5m | 9.5m | 9.5m | 9.5m |

| Diameter max suspended solids | 4mm | 4mm | 4mm | 4mm |

| Noise Level | 70 dB | 70 dB | 70 dB | 75 dB |

| Volume Stroke | 67 cc | 100 cc | 67 cc | 222 cc |

Frequency Asked Questions

A diaphragm pump is a type of positive displacement pump which uses a flexible diaphragm as the only moving part to create pressure and move fluid. It is typically used in applications where a low flow rate, high pressure, or a pulsating flow is required.

A centrifugal pump is a type of rotodynamic pump that uses a rotating impeller to create pressure and move fluid. It is typically used in applications where a high flow rate ir required.

An air operated double diaphragm pump also known as an AODD pump is a type of positive displacement pump which operates using compressed air instead of an electric motor. It consists of two flexible diaphragms connected by a shaft, which move back and forth to create suction and discharge cycles.

As compressed air enters one chamber, it pushes the diaphragm outward, forcing fluid out of that side whilst simultaneously drawing fluid into the opposite chamber. A set of check valves ensures that liquid flows in only one direction. The air supply then shifts to the other chamber, repeating the cycle and maintaining a steady flow.

AODD pumps offer versatility, as they can handle a wide range of fluids, including abrasive, viscous and corrosive liquids. They are self-priming and can run dry without damage, making them ideal for unpredictable flow conditions. Additionally, they feature a simple design with minimal moving parts, leading to low maintenance and easy repair.

Yes, they can run dry without damage, making them ideal for applications with variable flow or intermittent fluid supply. Unlike centrifugal pumps, which can overheat and fail without liquid, AODD pumps use air pressure to move diaphragms, allowing them to operate safely even when dry. However, while they won’t suffer immediate damage, prolonged dry running can increase diaphragm wear, so regular maintenance checks are recommended.

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Very good company with a wealth of expertise.