Many pumping applications demand a double pressurised mechanical seal arrangement due to the crystalline or abrasive nature of the liquid being handled.

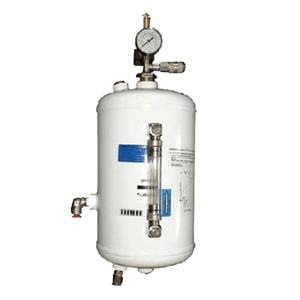

For these duties, the SS24 sealing system is ideal, providing a safe and simple method for pressurising double seals. Acting as if a totally self-contained, the SS24 also provides protection for the pump against dry running which stops the pump breaking-down meaning no large repair bill for your business.

The SS24 sealing system has been designed to provide a solution to the problem of pressurised flushing of a double mechanical seal. Totally self-contained, the system is delivered complete with sight glass, pressure gauge, pressure switch and quick-fit nylon hose and coupling.

Operation

Operating on the thermo-syphon principle which does not require any external pumping equipment, the reservoir is pressurised to one to two bar above the maximum discharge pressure of the pump. A pressure switch is wired to the motor starter so that if, for any reason, the pressure in the seal pot drops below the required level the motor will be cut-out and, if required, an alarm signal sent.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Discover the significant savings you can achieve and explore the potential financial benefits that await you.

Frequently Asked Questions

The SI system (International System, or System International in French) is the standard system of measurement used globally for scientific, industrial, and everyday purposes. It is based on the metric system and provides a consistent and coherent set of units for measuring various physical quantities such as length, mass, time, temperature, and more.

The SI system is built on seven base units, each representing a fundamental physical quantity. These base units are:

Meter (m) for measuring length

Kilogram (kg) for measuring mass

Second (s) for measuring time

Ampere (A) for measuring electric current

Kelvin (K) for measuring the temperature of a substance

Candela (cd) for measuring luminous intensity.

Best Efficiency Point (BEP) is the operating point at which a pump runs at its highest efficiency while minimizing energy consumption and wear. It

represents the optimal balance between flow rate and head, ensuring the pump delivers the best performance with the least amount of stress on its components.

Operating a pump away from its BEP—either too far to the left (low flow, high head) or too far to the right (high flow, low head)—can lead to problems such as cavitation, excessive vibration, increased energy costs, and premature wear on bearings and seals. Proper pump selection and system design aim to keep the pump as close to its BEP as possible to maximize efficiency, reduce maintenance costs, and extend pump life.

Lifecycle Cost (LCC) Analysis is a method used to determine the total cost of ownership of a pump over its entire operational lifespan. Instead of focusing solely on the initial purchase price, LCC considers all costs associated with the pump, including installation, energy consumption, maintenance, repairs, downtime, and disposal or replacement. By evaluating these factors, businesses can make informed decisions that minimize overall expenses and improve efficiency.

For pumps, energy costs typically make up the largest portion of LCC, often exceeding the initial purchase price. Other significant factors include maintenance and repair costs, which can increase if a pump operates outside its Best Efficiency Point (BEP) or is not properly maintained. By selecting energy-efficient models, implementing predictive maintenance, and considering materials that extend pump life, businesses can reduce LCC and achieve long-term cost savings while improving reliability and performance.

NPSHa stands for Nett Positive Suction AVAILABLE and NPSHr stands for Nett Positive Suction Head REQUIRED.

Now, what is the difference between NPSHa and NPSHr? Well, firstly NPSH is a measure of the pressure experienced by the fluid at the suction of the pump. This is always quoted in metres (or feet) rather than as a pressure because head is a fluid independent property. Keep in mind that a pump will always lift liquid to the same height regardless of the fluid's respective densities.

NPSHa (available) is a property of the system and is calculated by the system designer giving a value of the pressure on the suction side of the pump.

NPSHr (required) is a property of the pump. This is calculated by the manufacturer as the point where cavitation occurs. It is good practice to have a safety margin between 0.5m and 1m.

Trusted By The Best