Metal Finishing Industry

Reliable, Corrosion-Resistant Pumps for the Metal Finishing Industry

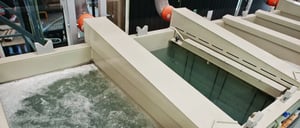

Metal finishing is a challenging industry for any pumping solution. For processes like electroplating, anodising or chemical etching, being able to rely on pump performance and lifespan is crucial. Crest Pumps has many years of experience in supplying corrosion-resistant pumps that can cope with the hazardous chemicals and extreme temperatures involved in metal finishing applications.

Challenges in the Metal Finishing Industry

Some of the challenges our customers in the metal finishing industry face are unique and require specialised pumping solutions and expertise:

Real Life Solutions for Real Life Challenges

Crest Pumps has a long-standing reputation for supplying high-quality pumps to the metal finishing sector.

Bowmill Metal Treatment

Implemented CSS Range pumps to handle aggressive solutions, reducing downtime and maintenance costs.

Twickenham Plating Group

Upgraded their pumping system to a Crest Pumps solution, improving efficiency and reliability in their electroplating process.

Our Pump Solutions for the Metal Finishing Sector

Crest Pumps provides a range of corrosion-proof chemical pumps for metal finishing applications. Our CSS Range of Magnetically Driven Chemical Process Pumps is the perfect choice for the more aggressive chemicals, providing a maintenance-free, leak-free service.

Featuring a standard 400mm column length. The vertical Surge range is suitable for all types of applications including metal treatment, tank emptying transfer and re-circulation

View Range

Built with a cantilever shaft design, CSS Pumps have no immersed bearings which allows the pump to run drywithout damage. Available in polypropylene or PVDF

View Range

Heavy duty process pumps designed with a metallic armour & high purity PFA-lining to handle the toughest applications & for transferring high purity aggressive chemicals

View RangeCut Costs and Maximise Efficiency.

Our pumps keep your operation flowingCertifications and Compliance

Crest Pumps is dedicated to producing the highest-quality, most reliable pumps for metal finishing. Our products are manufactured to represent the highest standards of performance.

-

ISO 9001:2015: The quality management system is certified, assuring the consistency and reliability of products.

-

Explosive Tending Environments: Explosion-proof pumps for hazardous environments are available under ATEX certification.

-

WRAS Approved Materials: They fully comply with safety and material regulations.

Why Crest Pumps for the Metal Finishing Industry?

Many metal finishing processes employ highly aggressive chemicals, necessitating pump construction from resistant materials to avert failures and costly down-time.

Any disruption to the pumping process may lead to defective coatings or inconsistent finishes that can affect product quality.

The operating cost for metal finishing could be tremendous, making it imperative to use energy-efficient pumps to minimise wastage and optimise productivity.

Trusted By The Best