Aerospace Industry

Chemical Pumping Solutions for the Aerospace Industry

Precision, safety and performance: these three elements are the backbone of aerospace manufacturing. From advanced component fabrication to surface treatment processes, every process must develop seamless reliability when handling fluids. Crest Pumps supports the aerospace industry with performance chemical pumps that are made to handle the most challenging of fluids, providing efficiency and compliance with the very high standards of the aerospace industry.

Crest Pumps has decades of experience working with many aerospace manufacturers, particularly Rolls-Royce and GKN Aerospace. These typically involve chemical transfer, surface treatment and wastewater management solutions that are robust and corrosion resistant. They ensure running efficiency, compliance with regulatory norms and cost efficiency for meeting the industry's very stringent requirements.

Challenges in the Aerospace Industry

Crest Pumps has decades of experience working with many aerospace manufacturers, particularly Rolls-Royce and GKN Aerospace. Some of the common challenges we have helped them to solve include:

Real Life Solutions for Real Life Challenges

Custom Vertical Pump for Rolls-Royce

In 2017, Rolls-Royce purchased three new pumps to transfer 114m3/hr of Kerosene, Avtur Jet A-1 and Avgas 100LL as part of the engine testing systems. Crest HD-HG-RS pumps were supplied constructed from 316 Stainless Steel and Atex Zone 1 certification.

Compact, Low-Maintenance Pumps for GKN

GKN Aerospace is a world leader in the supply of airframe and engine structures, landing gear, electrical interconnection systems, transparencies and aftermarket services

The AM50 ETFE Mag Drives were the perfect choice for their operations due to their small footprint, easy maintenance and pipework matching 1″ PVC connections.

Our Pump Solutions for the Chemical Sector

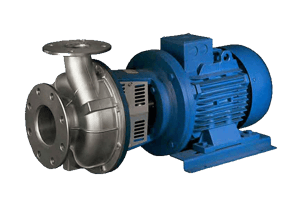

The HD-HG-RS ranges are suitable for a wide variety of applications including chemical transfer, pharmaceutical and food production. The modular design of this range makes the pump completely flexible to your business requirements

View Range

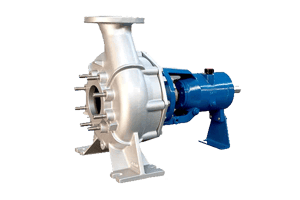

The RD-RG-RC-RB range of heavy duty end suction process pumps are designed for all applications from water to corrosive or solvents including ATEX Zone 1 and 2. Built to ISO2858 and En25199 and come with a choice of impeller designs to best fit your application

View Range

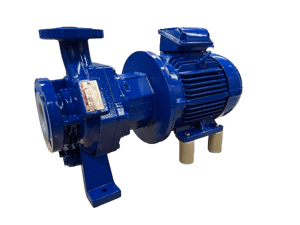

Heavy duty process pumps designed with a metallic armour & high purity PFA-lining to handle the toughest applications & for transferring high purity aggressive chemicals

View Range

USA made Truflo ANSI mag drive pumps range conforming to ANSI spec with quick deliveries. Sealless operation & all wetted parts are made from ETFE fluoropolymers.

View RangeIf you are looking for expert advice on which pump is best for your Aerospace application

Contact our team today.Certifications and Compliance

Crest Pumps is no stranger to the regulatory standards governing aerospace manufacturing and designs pumps with these rules in mind.

- Our chemical pumps meet and exceed requirements developed by ISO 9001 quality management systems, which ensures output consistency and traceability.

- Crest Pumps comply with the ATEX directive, which renders them operable in potentially explosive atmospheres.

Why Crest Pumps for the Aerospace Industry?

Crest Pumps continues to be a world leading partner in the aerospace industry for any company looking for high-performance fluid handling solutions.

We can supply the right pumps for the job every time providing you with complete peace of mind.

Crest Pumps is rightly proud of its green credentials. Sustainability remains a top priority in the design and materials we use.

Designed to meet all regulations and compliance requirements both in the UK and globally.

Trusted By The Best